The New Energy business based on the principle of Carbon Recycle and Circular Economy is a multi-trillion opportunity for India and the world.

It is also an opportunity to make clean and green energy abundantly available at an affordable price to every Indian, every Indian enterprise, and every Indian utility.

More than a business, this is our seva to save Planet Earth from the ravages of climate change.

Mukesh

Ambani

Chairman & Managing Director, RIL

Chairman & Managing Director, RIL

Helping India lead in the green energy future

At the RIL Annual General Meet in 2021, Chairman and Managing Director Mukesh D. Ambani announced an investment of over Rs 75,000 crore (USD 10 billion) in building the most comprehensive ecosystem for New Energy and New Materials in India to secure the promise of a sustainable future for generations to come.

We are committed to helping India lead in the Green New Energy future and are bridging the Green Energy divide in India and the world.

Our New Energy and New Materials business will be an optimal mix of reliable, clean and affordable energy solutions with hydrogen, wind, solar, fuel cells, and batteries.

A Fully Integrated Renewable Energy Ecosystem

Jamnagar, the cradle of our old energy business, is also the cradle of our New Energy business.

We are constructing the Dhirubhai Ambani Green Energy Giga Complex over 5,000 acres in Jamnagar with five giga factories for:

- Photovoltaic panels

- Fuel cell system

- Green Hydrogen

- Energy storage

- Power electronics

The Dhirubhai Ambani Green Energy Giga Complex will be among the largest such integrated renewable energy manufacturing facilities in the world.

Additionally, we are pursuing wind power generation by developing a manufacturing ecosystem for cost-efficient wind power generation at giga scale.

Investments for a better future

We are investing Rs 60,000 crore (approx. USD 7.2 billion*) to construct world-scale, state-of-the-art facilities to manufacture and integrate critical components of the New Energy ecosystem:

- Fully integrated solar photovoltaic manufacturing complex

- Advanced energy storage systems for integrated cells, battery packs, control manufacturing

- Electrolyser manufacturing facility

- Power electronics and semiconductor development

- Basic raw material and auxiliary materials manufacturing

- Research and Development facilities for all New Energy technologies

We will also invest in Glass and Polyolefin Encapsulant (POE) film manufacturing, both of which have natural synergies with our Chemical and Materials business.

We are investing Rs 15,000 crore (approx. USD 1.8 billion*) in value-chain, partnerships, and future technologies, including upstream and downstream industries, to create a fully integrated, end-to-end renewable energy ecosystem.

Further, we are developing an ecosystem for assisting Small and Medium Enterprises (SMEs) and entrepreneurs to embrace new technologies and innovations leading to captive use of Renewable Energy and Green Hydrogen.

We intend to invest in the state of Gujarat for Green Energy and other projects. We will also set up 10 giga watts (GW) of renewable energy capacity in Uttar Pradesh—the largest in the state.

End-to-end solar PV ecosystem

We are constructing a fully integrated, end-to-end solar photovoltaics (PV) manufacturing ecosystem, which will be one of the largest, most technologically advanced, flexible, and most cost-competitive solar giga factories globally.

The Jamnagar solar PV and cell module factory will be the first-of-its-kind 'quartz-to-module' facility globally, with components from quartz to metallurgical silicon, polysilicon, and ingots/wafers, that will be integrated with cells and modules.

This will take us a step closer to our target of establishing and enabling at least 100 giga watts (GW) of solar energy by 2030.

Fuel cell system

We are setting up a fuel cell giga factory for electricity and power generation. Fuel cells will progressively replace internal combustion engines. Fuel cell engines can power automobiles, trucks, and buses. They can also be used in stationary applications for powering data centres, telecom towers, emergency generators and micro grids and industrial equipment.

Battery giga factory

We are also setting up a battery giga factory by 2026 for manufacturing battery chemicals, cells and packs, as well as containerised energy storage solutions and a battery recycling facility. We aim to produce Lithium Iron Phosphate (LFP) based solutions at world beating lifecycle costs and we are fast-tracking commercialisation of our sodium ion battery technology.

Electrolyser

One of the most common methods of generating Green Hydrogen is by electrolysis of pure water through Electrolysers. Our electrolyser giga factory will manufacture modular electrolysers of the highest efficiency and lowest capital cost.

These can be used for captive production of green hydrogen for domestic use as well as for global sale.

Energy storage and Green Hydrogen production

We are integrating energy storage with wind and solar power generation at mega-watt scale in Jamnagar to provide grid-connected, round-the-clock electricity. We will also deploy batteries at grid-scale to convert intermittently captured photons into electrons for captive requirements, as well as for India’s growing energy needs.

For large scale and cost-competitive Green Hydrogen production, we will leverage our solar and wind energy storage integrated manufacturing ecosystem and set up a fully integrated, automated giga-scale electrolyser manufacturing facility.

Power electronics

One of the key components linking the entire value chain of green energy is affordable and reliable power electronics.

We are building significant capabilities in designing and manufacturing power electronics and software systems and integrating these with our capabilities of telecommunications, cloud computing and Internet of Things (IoT) platform.

We will build this through partnerships with leading global players to provide most affordable solutions, meeting global standards of performance, safety, and reliability.

Wind power generation

We are pursuing wind power generation by developing a manufacturing ecosystem for cost-efficient wind power generation at giga scale.

Our foray into carbon fibre—which is a significant cost driver in manufacturing wind blades—lends a unique advantage to further integrate and reduce the cost of wind turbines. Further, we will partner with the world’s leading technology players in wind equipment manufacturing to deliver cost-efficient solutions.

Accelerating net-zero carbon with bio-energy

Bio-energy will help replace fossil fuels with renewable alternatives to produce green fuels for power plants, industrial boilers, and transport sectors. Our target biofuels include Compressed Biogas (CBG), densified briquettes and pellets, Green Hydrogen, and bio-oils.

To accelerate our target of net-zero carbon by 2035, we are developing capabilities in bio-energy.

We are India’s largest bio-energy producer.

We have set up two demo units for Compressed Biogas (CBG) at Jamnagar and a commercial scale CBG plant at Barabanki, Uttar Pradesh—commissioned in a record 10 months.

We aim to utilise a share of surplus agro-waste to convert to various forms of bio-energy. We target to establish 100 CBG plants in the next five years, consuming 5.5 million tonnes of agro-residue and organic waste. This will mitigate ~2 million tonnes of carbon emissions and help produce 2.5 million tonnes of organic manure annually. We expect this to result in a reduction of 0.7 million metric tonnes per annum (MMTPA) of imported liquefied natural gas.

Our Investments & Acquisitions in New Energy and Clean Mobility

Through our subsidiary, Reliance New Energy Ltd (RNEL), we have made the following investments and acquisitions:

Faradion Ltd

RNEL has acquired leading global sodium-ion battery technology company Faradion Ltd. for an enterprise value of GBP 100 million. RNEL is also investing GBP 25 million as growth capital to accelerate commercial roll out.

To learn more, please visit www.faradion.co.uk

Lithium Werks

RNEL has acquired assets of LFP batteries provider Lithium Werks for USD 61 million. Lithium Werks is a leading provider of cobalt-free and high-performance Lithium Iron Phosphate (“LFP”) batteries.

To learn more, please visit www.lithiumwerks.com

REC Solar Holdings AS (REC Group)

RNEL has acquired REC Solar Holdings AS (REC Group), one of the world’s leading solar cells/panels and polysilicon manufacturing companies, for an enterprise value of USD 771 million.

To learn more, please visit www.recgroup.com

SenseHawk

Reliance has invested USD 32 million to acquire a majority stake in SenseHawk, an early-stage California-based developer of software-based management tools for the solar energy generation industry. Founded in 2018, SenseHawk helps accelerate solar projects from planning to production by helping companies streamline processes and use automation.

SenseHawk has helped 140+ customers in 15 countries adopt new technology for their 600+ sites and assets totalling 100+ GW. SenseHawk’s Solar Digital Platform offers end-to-end management of solar asset lifecycles.

To learn more, please visit www.sensehawk.com

Forging Global Partnerships for Sustainable Growth

We have forged strong global partnerships to co-create New Energy solutions for India and the world.

Sterling & Wilson Solar

RNEL has acquired a 40% stake in Sterling & Wilson Solar, one of the largest EPC and O&M providers globally, to provide turnkey solutions in the New Energy value chain.

To learn more, please visit www.sterlingandwilson.com

NexWafe

RNEL has invested USD 29 million (EUR 25 million) in Germany’s NexWafe and partnered with them for the joint technology development and commercialization of high-efficiency monocrystalline “green solar wafers”.

NexWafe’s unique patented technology is expected to drastically lower costs and make solar photovoltaics the lowest-cost form of renewable energy available and build large-scale wafer manufacturing facilities in India.

To learn more, please visit www.nexwafe.com

Stiesdal A/S

RNEL is collaborating with Denmark’s Stiesdal A/S on manufacturing of their HydroGen Electrolyzers in India, which will produce hydrogen at a significantly lower cost compared to current levels, thus paving the way for rapid decarbonization and commercialization of affordable Green Hydrogen.

To learn more, please visit www.stiesdal.com

Caelux Corporation

RNEL is investing USD 12 million for a 20% stake in Caelux to accelerate its product and technology development, including construction of its pilot line in the United States for expediting the commercial development of its technology. RNEL and Caelux have also entered into a strategic partnership agreement for technical collaboration and commercialization of Caelux’s technology.

Caelux is an industry leader in the research and development of perovskite-based solar technology. Its proprietary technology enables high efficiency solar modules that can produce 20% more energy.

To learn more, please visit www.caelux.com

Reliance New Energy Council (2021-2024)

The Reliance New Energy Council (NEC) comprises some of the finest minds globally. These members help us validate our strategies and embrace disruptive pathways to achieve our goals. NEC members are experts at the top of their fields who will guide us on technical strategy, help identify opportunities, and advise us on partnerships worldwide. They are global advocates and thought leaders of the New Energy business. With such luminaries in our Council, Reliance hopes to transform the world and make it an even better place.

The NEC Charter

- Accelerate the market-led transition of Reliance to clean energy, with the aim of becoming net-zero carbon by 2035

- Reinvent Reliance to become a New Energy major with a focused technology roadmap of 5 to 15 years – including an optimal mix of clean, affordable energy

- Formulate strategies for business configuration, operations, models, manufacturing, project development within an ever-evolving Indian and global policy landscape.

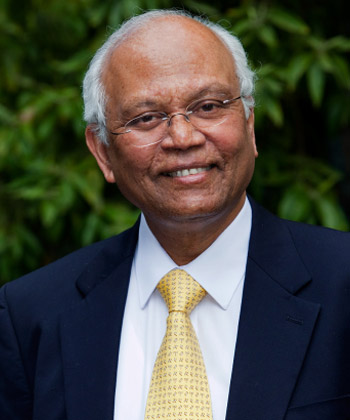

R. A. Mashelkar

Chairman, New Energy Council; Former Director General of CSIR, India

read more

Mukesh D. Ambani

Chairman and Managing Director, RIL

read more

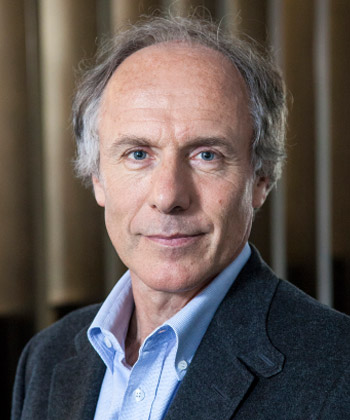

Alan Finkel

Former Chief Scientist of Australia; Chairman, Low Emissions Technology Investment Advisory Council, Australia

read more

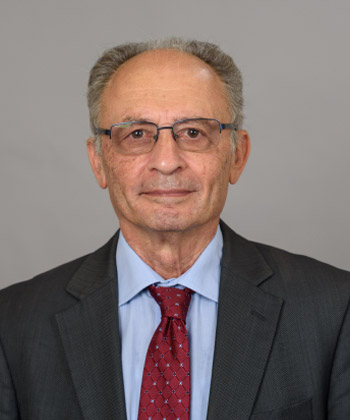

David Milstein

Professorial Chair of Organic Chemistry, Weizmann Institute of Science, Israel

read more

Geoffrey Maitland

Professor of Energy Engineering, Imperial College, London

read more

Henrik Stiesdal

Founder and CTO, Stiesdal, Denmark

read more

Martin Green

Scientia Professor, University of New South Wales (UNSW), Australia

read more

Rachid Yazami

Founding Director and CTO, KVI Holdings, Singapore; Former Research Director, CNRS, France

read more

Robert Armstrong

Director, Massachusetts Institute of Technology Energy Initiative (MITEI), USA

read moreNew Materials

Consistent with our ambition to decarbonise our businesses and our vision for New Materials, we will build in phases India’s first and one of the world’s largest carbon fibre plants at Hazira with a capacity of 20,000 metric tonnes per annum (MTPA) based on Acrylonitrile feedstock.

Our carbon fibre platform will include carbon fibre and carbon fibre reinforced plastics. Our target is to be among the top three players globally in the carbon fibre and carbon fibre reinforced plastic composites.

Our foray into manufacturing carbon fibre at large scale also provides us with a unique advantage to integrate and reduce the cost of wind turbines, as carbon fibre is a significant cost driver in the manufacturing of wind blades.

We aim to complete the first phase of the carbon fibre plant during 2025. The plant will have flexibility to produce highly profitable specialty grades to cater to diverse end uses.

Besides other applications, carbon fibre composites are also used to meet the rapidly growing light weighting requirements of mobility and renewable energy. Thus, carbon fibre promises to be a multi-decade growth engine for our Oil-to-Chemicals business.

We are championing sustainability through circular economy and are India’s leader in recycling polyesters and plastics. We will strengthen our leadership position in PET recycling by more than doubling our bottle recycling capacity to 5 billion bottles a year.

We have developed an innovative chemical recycling pathway to enable conversion of waste plastics to valuable refinery feedstock.

Our scientists have also developed pathways to produce biodegradable and compostable plastics to completely replace single-use plastics. We are on our way towards attaining global leadership in recycling and producing sustainable materials.

Join Us

Reliance is the place for those who dare to tackle the seemingly impossible challenges of our society and invent solutions that overcome them. If you are passionate about sustainability, renewable energy solutions, and truly care about people and planet, come be part of the Reliance family!

Join us to co-create the New Energy future for India and the world.

Send us your CVs at careers.newenergy@ril.com or visit us for all open positions. www.careers.ril.com/newenergy/