We are committed to embracing new technologies to convert our CO2 into useful products and chemicals. We have already made substantial progress on photosynthetic biological pathways to convert our CO2 emissions at Jamnagar into high-value proteins, nutraceuticals, advanced materials and fuels. We will develop next-gen carbon capture and storage technologies.

We also have proprietary technology to convert transportation fuels to valuable petrochemical and material building blocks. And at the same time, we will replace transportation fuels with clean electricity and hydrogen. On successful implementation of this strategy, Reliance targets to become net carbon zero by 2035.

Sourcing the world’s first carbon-neutral oil

In 2021, in line with Reliance's net-zero carbon commitment, we sourced two million barrels of the world’s first carbon-neutral oil from the Permian basin.

Leading India into the Circular Economy

PET recycling capacities

Starting as early as 2001, Reliance helped set up a reverse supply chain for PET. This helped provide employment to many unskilled people who participated in the collection, segregation, baling, and transportation of post-consumer PET bottles. This initiative also helped entrepreneurs set up PET recycling units over two decades, taking India’s post-consumer PET recycling rate to one of the highest in the world, at 85-90%.

Reliance is proud to support this as one of the largest recyclers of PET bottles in India, recycling over 2 billion PET bottles annually.

To enhance our circular economy footprint, we are doubling our PET recycling capacity to 5 billion bottles, to support India in maintaining an over 90% recycling rate.

Reverse vending machines for PET collection

Reliance has sponsored over 100 reverse vending machine installations across major cities in India.

Polyolefins Recycling

We are working with recycling companies to create a large portfolio of recycled products made from used polyolefin plastics. Our brands EcoRepol™ and EcoRelene™ are post-consumer recycled Polypropylene (PP) and Polyethylene (PE) products that encourage the circular economy in India. These grades will have usage in select applications for non-food products to help the plastics industry adopt principles of circular economy.

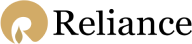

GreenGold™ recycled fabrics

GreenGold™ fabrics by R|Elan™ are an eco-friendly product made from recycled PET bottles using renewable energy, with one of the lowest carbon footprints globally. These fabrics are used in a wide range of apparel in India and globally. We work with our value chain partners including spinners, weavers, knitters and processors to deliver end-to-end solutions for their sustainability needs.

Recron® GreenGold

Recron® GreenGold is an eco-friendly product made from recycled PET bottles using renewable energy, with one of the lowest carbon footprints globally.

Extended Producer Responsibilities

Reliance adopts responsible plastic and e-waste management strategies across Reliance Retail, which is authorised to collect e-waste and fulfil extended producer responsibilities.

Waste to Road: ReRoute™

RIL launched ReRoute™, a waste and multi-layer plastics-to-road initiative. As part of this, we built a 40 km road in Nagothane, Maharashtra, a one-km road inside the RIL-RCP campus at Ghansoli, Navi Mumbai, and a 12 km road at our Vadodara unit using end-of-life plastics to enhance road quality. ReRoute™ has been tested and approved by CSIR-CRRI and is now commercially available.

RelWood™: An eco-friendly alternative to wood

Created using cutting-edge patented German technology, RelWood™ is a strong, durable and versatile material that looks and feels exactly like wood. This 100% sustainable and recyclable material is made without cutting a single tree, thus offering an eco-friendly alternative to wood.

Circular Design Challenge (CDC)

Launched by RIL’s “Fashion for Earth” programme in collaboration with UN Environment and Lakmé Fashion Week (LFW), the CDC is India’s biggest sustainable fashion award. CDC raises awareness on textile waste generation and helps identify solutions to reduce the impact caused by waste in the fashion and textile industry.

It achieves this by promoting environmental champions in the Indian fashion and textiles industry. Winners receive a prize of Rs 20 lakh and a chance to showcase their collection at LFW.

Supporting Versova beach clean-up to remove plastic waste

Reliance has been providing support to plastic waste clean-up activities at Versova beach in Mumbai through Bobcats with beach cleaning attachment.

Alliance to End Plastic Waste (AEPW)

Reliance is one of the founding members of AEPW and the only Indian company to participate in this global effort to eliminate plastic waste. As of March 2021, the Alliance had five projects in various stages of implementation on the ground in India. When the projects reach full speed, cumulative forecast impact is to prevent 90,000 tonnes of plastic waste from leaking into the environment by 2025. These projects are then expected to deliver 40,000 tonnes per annum on an ongoing basis after stabilization.

Waste to Oil – Chemical Recycling

We have initiated a detailed R&D programme to transform Multi-Layered Packaging (MLP) waste to pyrolysis oil for use at refineries and crackers. This pyrolysis oil will be used to produce plastics again. As part of this programme, our R&D team works with start-ups to commercialise “waste-to-fuel” projects for India by developing cutting-edge technology.